This tutorial which is part of our SAP MM course talks about SAP Purchase Requisition. You will learn what is a purchase requisition in SAP, what role does in play in procurement processes, and how to create it.

SAP Purchase Requisition is a document created by SAP ERP during the requirement determination phase. To understand the meaning and the use of SAP Purchase Requisition, it is essential to understand the Procure to Pay business process and SAP ERP Materials Management functionality.

Companies acquire goods and/or services in order to meet their needs by purchasing them. These purchases are happening in a series of activities named Purchase to Pay business process.

SAP has introduced SAP ERP software that is assisting companies in managing their daily work including the Purchase to Pay process. SAP has therefore designed functionality to cover this entire Purchase to Pay process and called it Materials Management.

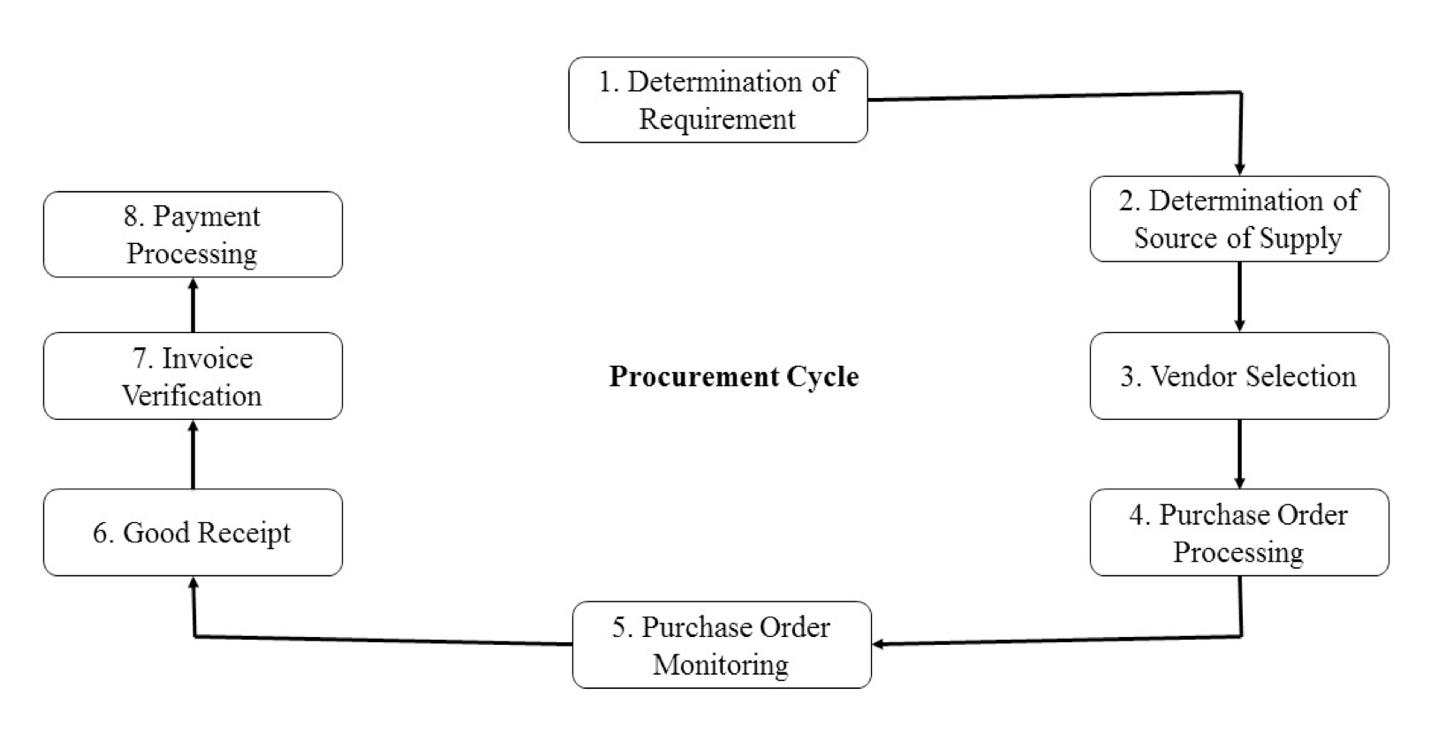

The Purchase to Pay process in Materials Management is based around a general cycle of actions called the procurement cycle, which comprises a series of eight steps known as:

The Determination of Requirement is the first phase of the procurement cycle and the phase where SAP generates a document called SAP Purchase Requisition.

As depicted on the figure below, the determination of requirement step starts the procurement cycle. It is a step at which users or departments determine materials requirements manually or automatically using materials planning and control. SAP Purchase Requisition can be defined as a procedural method by which users or departments can request the purchase of goods or services, and it will contain information such as the material or service to be procured, a required date of delivery, and a quantity. SAP Purchase Requisition is either manually created (directly created) or automatically created (indirectly created).

This part describes the steps how a requisitioner will generate SAP purchase requisition by manually creating it.

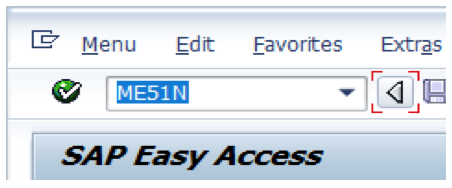

In order to do that, one can type the transaction code ME51N in command field.

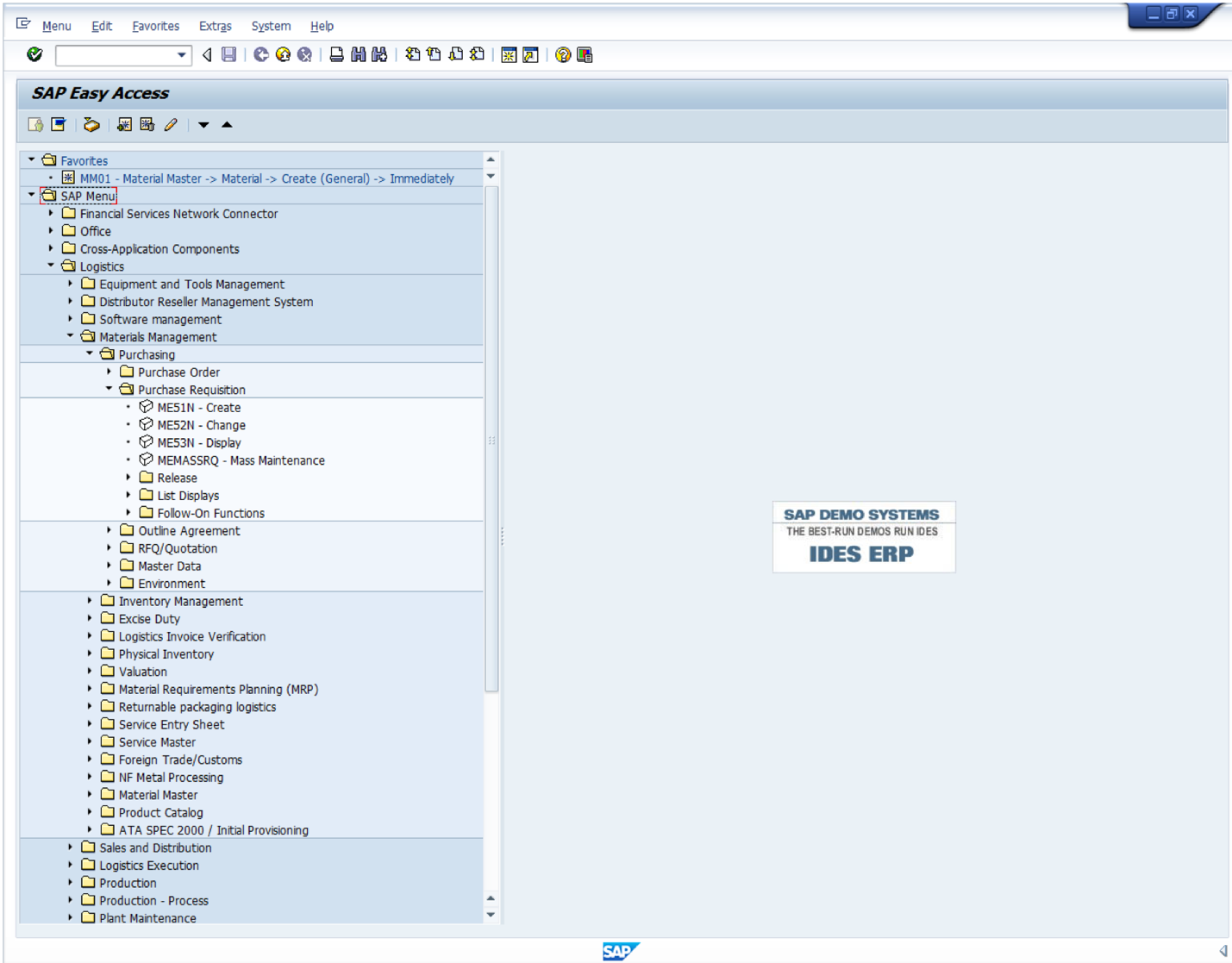

Alternatively, one can navigate to the following SAP menu path:

Logistics > Materials Management > Purchasing > Purchase Requisition > Create

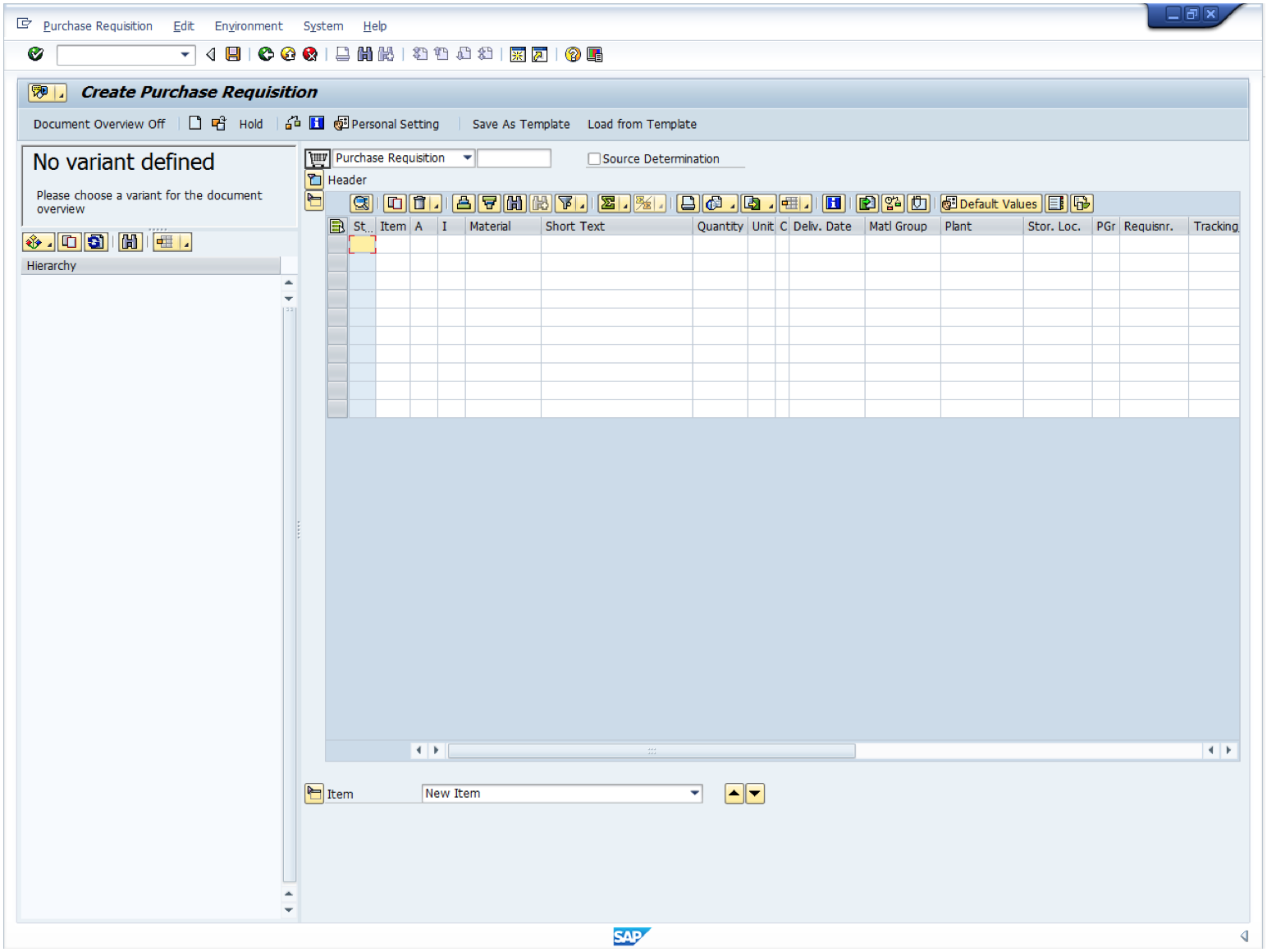

Then if not open already, one should press the button to display the items area of SAP purchase requisition as depicted in the next screenshot. Some fields that are not visible can be viewed if the horizontal scrolling bar is scrolled at the right side.

A purchase requisition can be created with a material master record or without it.

SAP business processes use master data on a long-term basis. Centrally created, all applications and authorized users can utilize it. It is therefore a common way to purchase a product or service that already has a material master record.

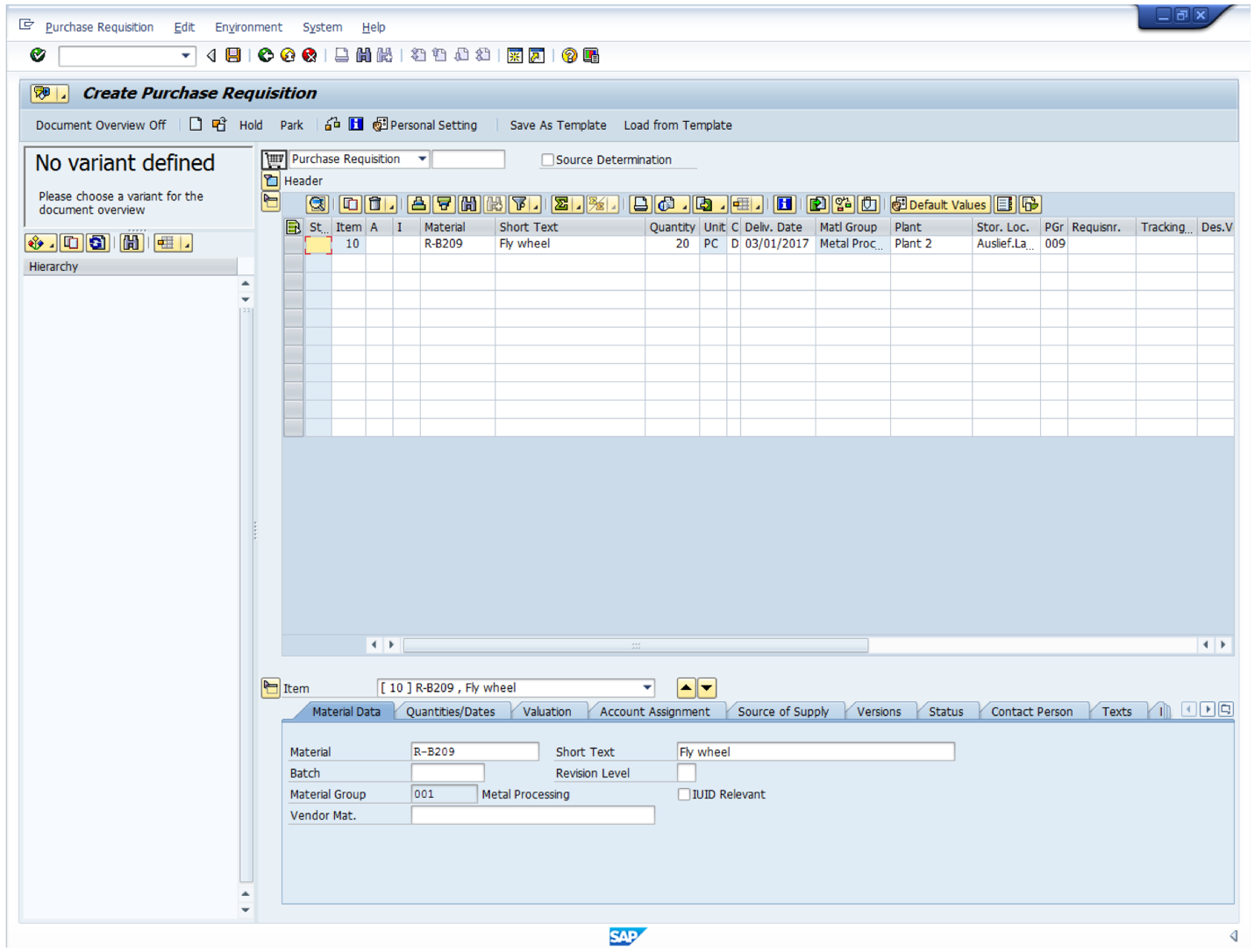

SAP purchase requisition for a material having a material master record will require a requisitioner to enter the following information:

Moreover, after entering the above information and pressing on Enter button, the requisition process will fill up by default the information into some of the blank fields.

Let us explore some of the information requested by the purchase requisition screen. We will not explain all of them but I am inviting you to use the F1 and F4 button to learn more about each field you want to know. The important fields are:

The purchase requisition number that is an attribute of a configured document type. A document type defines the internal and external number ranges that are used for SAP purchasing requisitions. There are two documents types delivered by the standard SAP system named NB and TB. NB is a standard purchase requisition.

The source determination that can be selected if there is a need for the system to carry out an automatic source selection.

The account assignment category, which determines what type of accounting assignment data is required for purchase requisition. It can be a cost center, a cost object, a general ledger account, and an asset

The plan and storage location that are entered whether the location where the materials are to be shipped to is known.

This kind of requisition is created the same way as the requisition with a master record. However, as there is no material master record for the good or service the following information will have to be entered:

In this case, it is essential to enter an account assignment category to direct the cost to a specific account. We will be using U, which will direct the requisition to an unknown account. There are also other options:

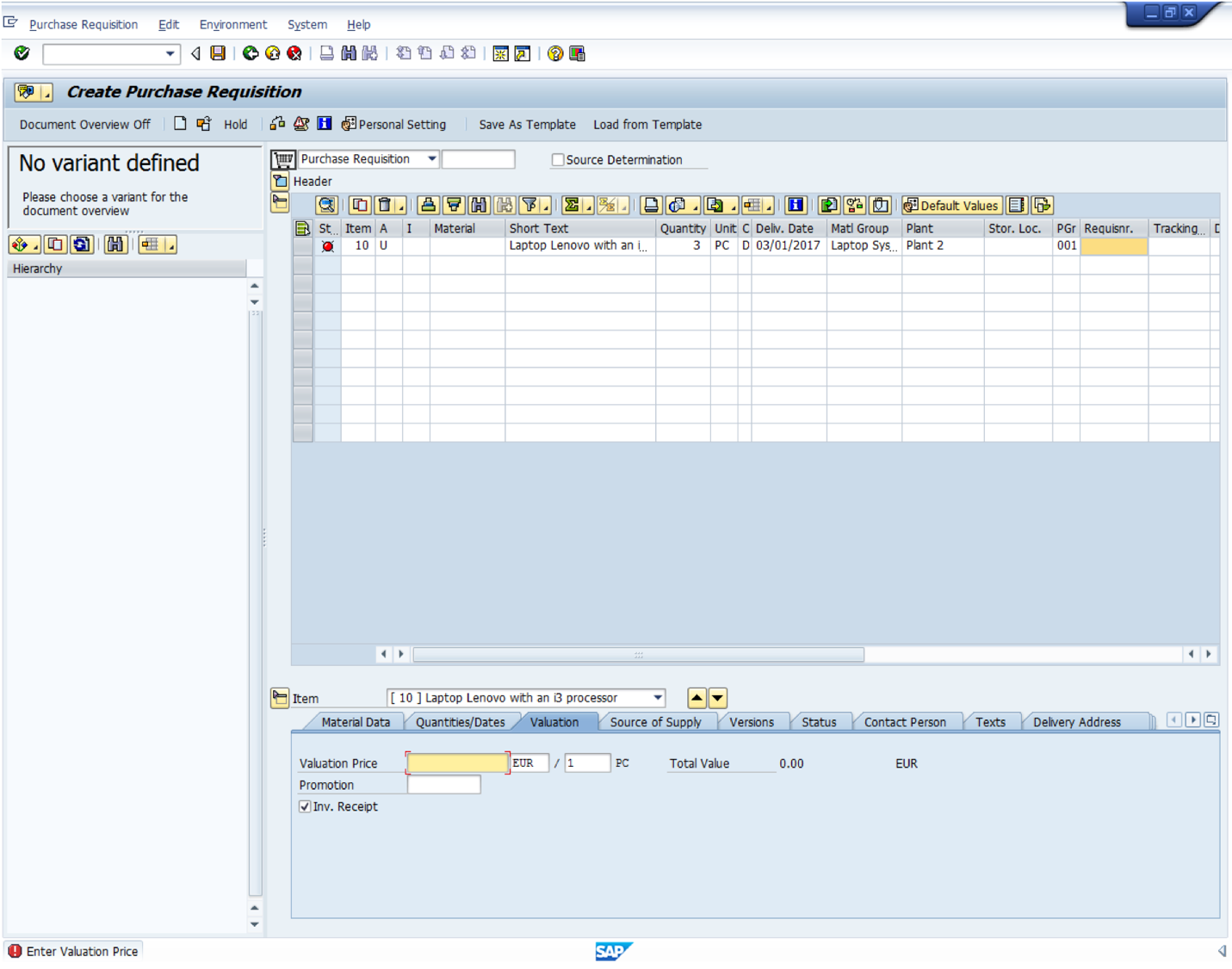

After pressing Enter button, an error message in the form of a red mark on the item line (in the column Status) will appear.

![]()

On the SAP status bar, an error message will be asking you to enter a valuation price under the valuation tab.

![]()

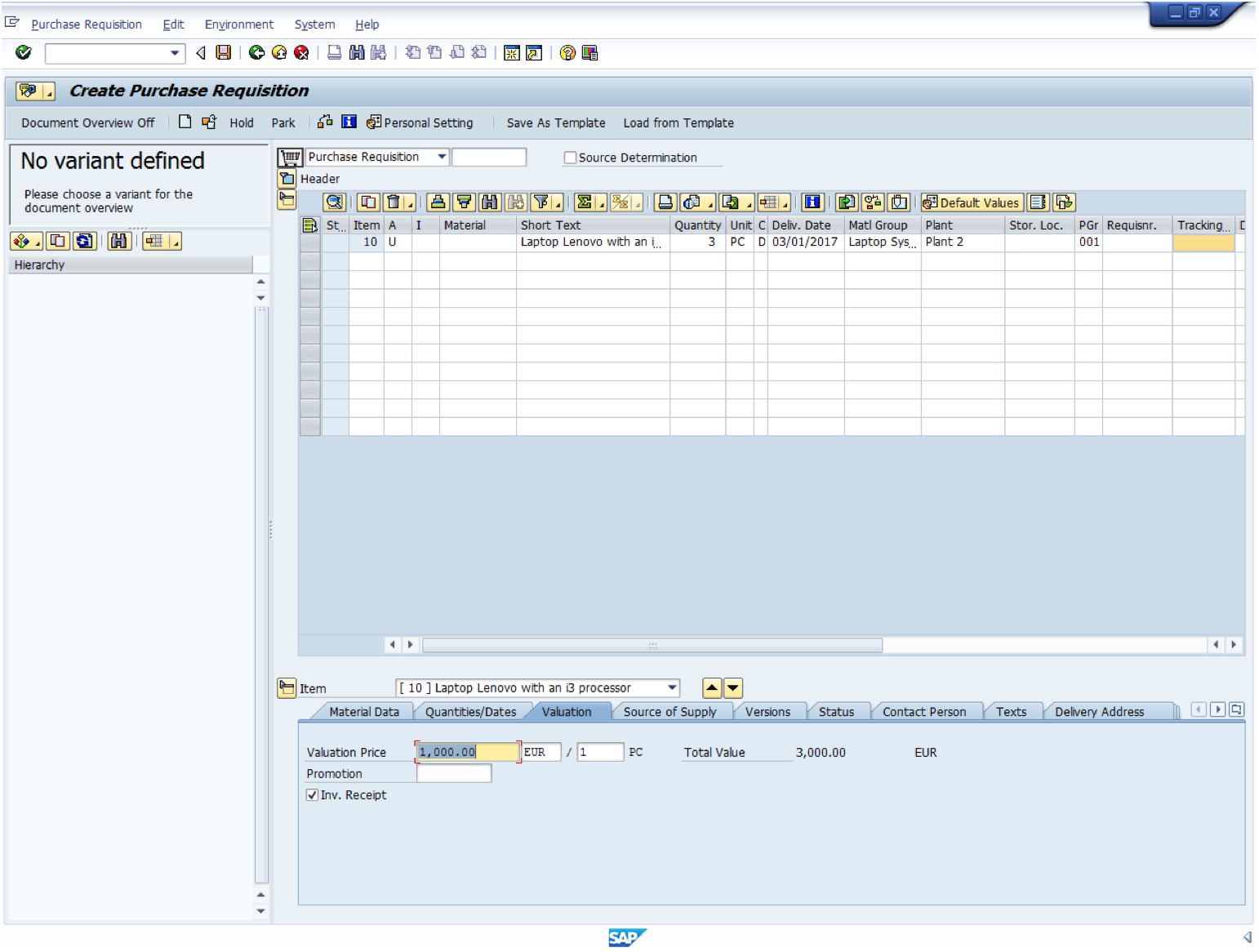

The valuation tab is appearing in a form under the following Item button.

![]()

It is important to notice that during the creation of SAP purchase requisition with a material master record a similar form was appearing and it was listing the item master record information on various tabs. In this case, there is no valuation price.

Enter the following information and press Enter button:

The error message will disappear and the purchase requisition process will ready for the next step.

Creation of SAP purchase requisition is finished by clicking on the save button to save the requisition in SAP database and to receive the purchase requisition number that will be displayed on the SAP Easy Access status bar. This action is the same for the two types (with and without material master record) of manually created SAP purchase requisition that we discussed.

![]()

SAP purchase requisition is created automatically when it is generated by other SAP processes that include:

Let us briefly describe how SAP purchase requisition will be created in each of these processes.

SAP routing and the bill of materials (BOM) are determining how the production order is working. SAP routing is a sequence of the operation that take place and the bill of materials (BOM) is the recipe leading to the production of the final material. In the routing, an operation may need a material to be sent out for external processing service and the bill of materials may call for a material that is a non-stock item. For both cases, SAP purchase requisition will be created.

Maintenance order is created for plant maintenance operations on equipment at the plant. A maintenance order has a list of operations that has to be performed. The operations give the maintenance user a systematic list of what need to be done and the materials needed for each step. In the operation, they may be a need for a non-stock material and the maintenance order may need an external operation. For both cases, SAP purchase requisition will be created.

In SAP project system, the network is an object consisting of a set of instructions that tell the project users what tasks need to be performed, in what order, and by what date. A network will create SAP purchase requisition(s) for non-stock materials and external services, if it is configured to allow creation of SAP purchase requisition as soon as it has been released.

The consumption-based planning module can create SAP purchase requisition based on its calculations.

SAP purchase requisition can be changed, displayed, closed or followed on by a function. The transaction codes allowing this processing are:

SAP Purchase Requisition allows organizations to fulfill the following business processes:

Without it, end users would be responsible for purchasing decision which can it turn lead a company to non-optimal procurement.

Did you like this SAP MM tutorial? Have any questions or comments? We would love to hear your feedback in the comments section below. It’d be a big help for us, and hopefully it’s something we can address for you in improvement of our free SAP MM tutorials.

Navigation Links

Go to overview of the course: SAP MM Training

Really intetresting

But in the field “SAP Purchase Requisition Transactions” of this tutorial, it is mentioned ME54N as t-code to display purchase requisition.

But isn’t it ME53N to display purchase requisition and ME54N to release PR?.

Kindly share a process for Purchase Requisition > For Raw Material to Finished Product at Venor’s work.

Which Material is to be enter in Purchase Requisition, Raw Material or Finished Product Material. For A Material which is going to be sent for vendor works for Some Activities (i.e Machining, Testing, etc.) then how this is to be process?